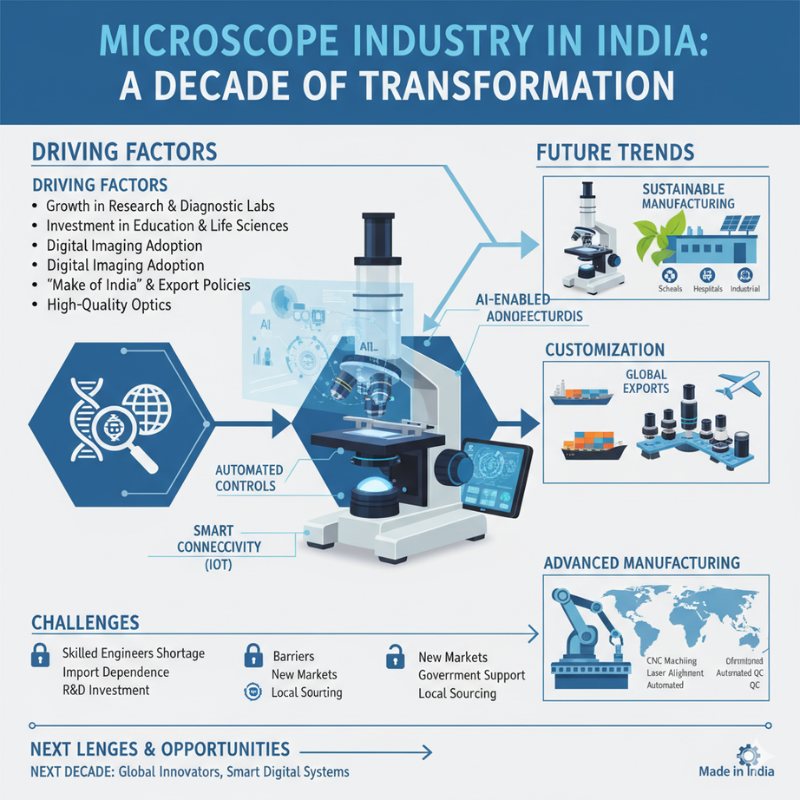

The Indian microscope industry is moving toward innovation and smart design. Research institutions, hospitals, and schools are demanding advanced instruments. Each microscope manufacturer in India is improving optical systems, adding digital features, and aligning production with global standards. The next decade will transform how microscopes are designed, produced, and used.

CLICK HERE – for Microscope Collection

Overview of the Microscope Industry in India

Microscope manufacturers in India have grown from small suppliers into specialized producers of laboratory instruments. Earlier, they made basic optical microscopes for schools. Now, they produce digital and automated models for medical and industrial work.

Indian laboratories are expanding in research and diagnostics. Biotechnology and pharmaceutical industries depend on precision tools. Many institutions prefer local products due to ease of maintenance and faster support.

Microscope manufacturers are also exporting to Africa, Asia, and Europe. Better quality control, ISO certification, and improved assembly systems have strengthened India’s presence in the global market.

Factors Influencing the Growth of Microscope Manufacturers in India

Several clear factors are shaping the future of this sector.

- Growth in research labs and diagnostic centers

- Rising investment in education and life sciences

- Wider adoption of digital imaging systems

- Support from “Make in India” and export policies

- Focus on high-quality optical glass and mechanical precision

Each microscope manufacturer in India that invests in digital upgrades and product innovation gains an edge in the market.

Future Trends Defining Microscope Manufacturer in India

Technology and production processes are driving big changes. Indian manufacturers are adapting quickly to stay relevant.

Shift Toward Digital and AI-Enabled Microscopes

Digital microscopes are replacing traditional models. They display images on screens, record data, and allow live sharing. AI-assisted analysis detects sample patterns quickly and improves accuracy.

Microscope manufacturers in India are adding AI tools that handle image processing and measurement automatically. These systems reduce user error and improve workflow in research and healthcare labs.

Integration of Automation and Smart Connectivity

Automation improves speed and precision. Automatic focusing, brightness control, and calibration simplify operations. IoT-based connectivity allows labs to share and store data easily.

Smart microscopes help researchers manage data across teams. Files can be labeled, saved, and retrieved quickly. Many microscope manufacturers now integrate these features into new product lines.

Sustainable Manufacturing Practices

Each microscope manufacturer in India is now expected to follow sustainable production standards. Energy-efficient assembly, recyclable materials, and low-emission equipment are becoming common.

Some manufacturers use solar-powered plants or reduce plastic use in casings. Green practices lower costs and attract clients who value responsible production.

Customization for Specific Applications

Different users require different models. Schools need simple microscopes for learning. Research centers need digital versions with camera support. Industrial users prefer microscopes designed for metals and surfaces.

Microscope manufacturers in India are creating flexible configurations. Buyers can select magnification range, lighting type, and imaging software. Custom designs make microscopes more practical and efficient.

Expanding Export Opportunities

Exports are rising every year. Indian microscope manufacturers are gaining visibility in global markets such as the Middle East, Africa, and Latin America.

Export success depends on optical accuracy, packaging, and certification. Indian companies that maintain global standards and competitive pricing are earning steady demand.

Technological Advancements in Manufacturing

Manufacturing technology is becoming smarter. Computer-aided design improves accuracy and consistency. CNC machining and laser alignment ensure perfect component fit.

Microscope manufacturers in India are also using automated inspection systems. Every product is tested for optical clarity, focus stability, and light intensity. Quality checks happen at each production stage.

Modern microscopes use LED lighting, digital cameras, and compact electronics. These features improve performance and extend lifespan.

Barriers for Microscope Manufacturers in India

Growth is steady but still limited by several factors.

- Shortage of skilled optical engineers

• Dependence on imported sensors and optical glass

• Limited R&D investment among smaller companies

• Inconsistent product quality across small-scale producers

• Competition from established international brands

A microscope manufacturer that builds local expertise, invests in technology, and standardizes production will move ahead faster.

New Opportunities for Microscope Manufacturer in India

Opportunities are expanding across education, healthcare, and industry. Schools and colleges need more microscopes for digital labs. Hospitals and private labs are upgrading to modern diagnostic tools.

Manufacturers can target these users with new designs. Portable and handheld microscopes are gaining attention in field research. Industrial microscopes for inspection and quality control are growing fast.

Government incentives under “Make in India” help local producers. Tax benefits and export assistance support medium-scale microscope manufacturers in India. Partnerships with universities also strengthen R&D and product testing.

Using Indian-made optical glass and components helps reduce import costs. Local sourcing improves delivery speed and supply chain stability.

Modern Trends in Product Design

Design trends are becoming simpler and more functional. Compact bodies, smooth focusing systems, and ergonomic stands improve user comfort.

Microscope manufacturers are adding built-in digital screens and camera attachments. Wireless transfer options make collaboration easier between labs. Modular microscopes that allow lens or lighting upgrades are gaining popularity.

Good design now focuses on clarity, usability, and speed.

The Future Direction of Microscope Manufacturing in India

The coming decade will mark the emergence of significant advancement for every microscope manufacturer in India. In the last decade, the adoption of automation, AI and sustainability will drive production strategies around manufacturing. The manufacturers involved in research, developing worker capabilities to test better and to provide a) consistent high quality incorporated with experiences will experience sustained growth.

The advanced biotechnology and clinical testing sectors will augment the demand for bespoke microscope abilities. Quality assurance, repeatable optical qualities and streamlined service support will create brand differentiation within microscope manufacturers. As a whole, microscope manufacturers in India find themselves with unprecedented growth opportunities within the global marketplace. This growth opportunity will not change rapidly and lead by consistent actions, transparent and collaborative policies and mechanisms that promote innovative practices.

Those manufacturers that respond early to all to smart design, sustainability and optical design will helped defined a new era of Indian manufacturing in microscopy.