Laminar air flow systems give you a controlled work zone with a steady airflow. The airflow keeps unwanted particles away from your samples. You use these systems in labs, microbiology rooms, pharma units, and clean process lines. The purpose is to protect your work from airborne particles. The system pulls air through a high-efficiency filter and sends that air across the workspace in a single direction. The direction is smooth. The airflow speed stays uniform. This creates a clean area for sensitive tasks.

What is Laminar Air Flow

Laminar Air Flow is a closed workstation designed to protect your samples from airborne dirt. The system pushes filtered air in one direction across the work zone. You get a stable and particle-controlled surface where you prepare your samples.

You use these systems when you handle microbiological cultures, sterile liquids, chemical samples, small instruments, and analytical components. The benefit of this system is that you get a clean and stable environment for consistent outcomes.

Laminar Air Flow Definition

Laminar air flow means a flow of air in a single direction with minimal turbulence. The air moves at the same speed throughout the system. The system uses HEPA filters to trap particles before the air reaches your workspace.

This gives you:

• Steady airflow

• Uniform speed

• Particle controlled zone

• Lower contamination risk

Types of Laminar Air Flow

You choose a type of Laminar Air Flow based on the direction of airflow and the level of sample protection needed.

Horizontal Laminar Air Flow

A horizontal Laminar Air Flow pushes air from the back of the cabinet to the front. The airflow moves directly toward you.

Benefits:

• Strong particle control

• Smooth airflow pattern

• Good protection for samples

• Useful for plate pouring, media work, and electronic component handling

Limitations:

• Less personal protection

• Needs more bench space

• Requires careful hand movement to avoid blocking airflow

Vertical Laminar Air Flow

Benefits:

• Better personal protection

• Smaller footprint

• Ideal for microbiology labs

• Lower risk of airflow blockage

Limitations:

• Air hits the work surface directly

• Needs careful height management of tools

Benchtop Laminar Air Flow

Benchtop models are compact units. You place them on an existing table. They give you a clean surface for small tasks. They are common in college labs, QC rooms, and field stations.

Stand Mounted Laminar Air Flow

Stand mounted units come with their own frame. These are bigger systems used in large labs. They support larger equipment and more complex tasks.

Reverse Flow Laminar Systems

Some advanced systems draw air from the front and filter it before release. These are used in pharma lines where operator exposure must stay low.

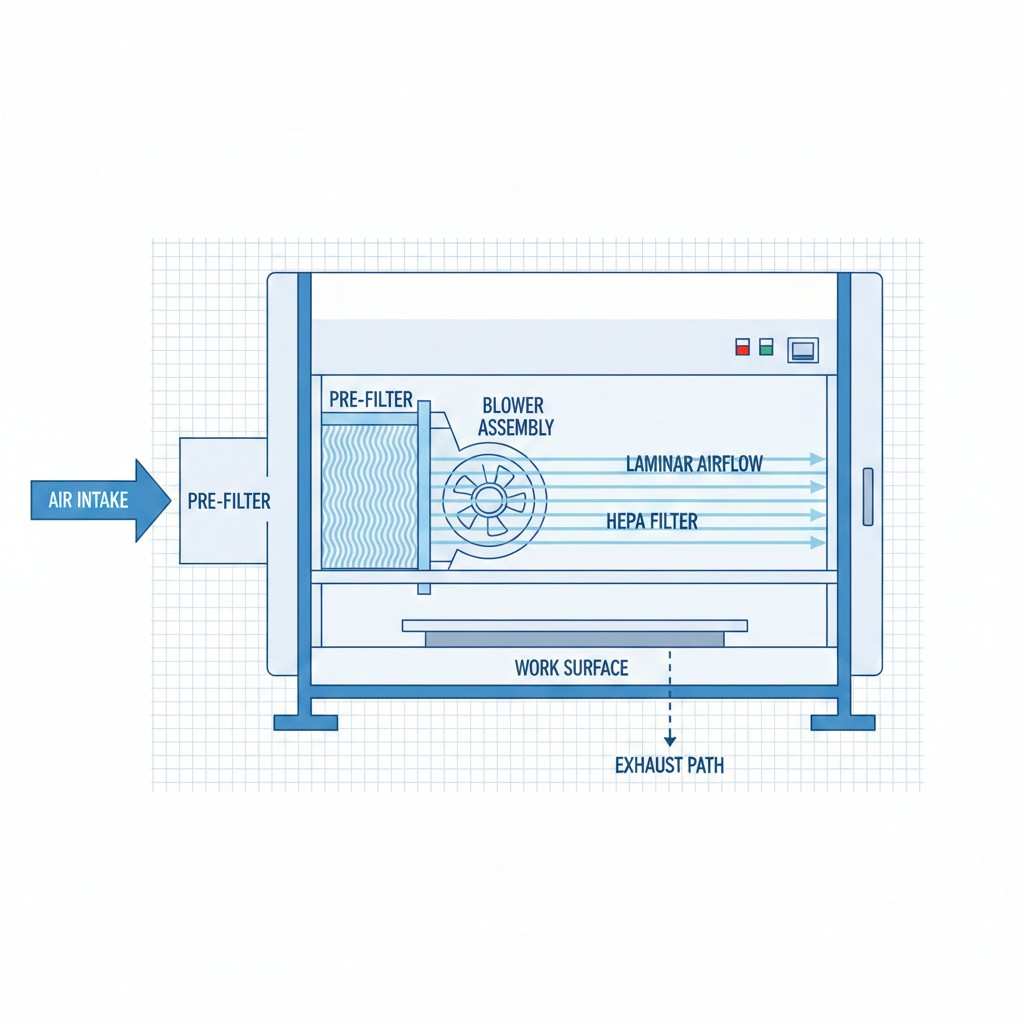

Laminar Air Flow Diagram

A standard Laminar Air Flow diagram shows you:

• Air intake

• Pre filter

• HEPA filter

• Blower assembly

• Work surface

• Exhaust path

Air enters through the pre filter. The blower pushes the air to the HEPA filter. The HEPA filter removes particles. The filtered air moves in a straight line across the workspace. The air exits through front openings or side paths depending on the model.

You can read a diagram to understand airflow direction, filter position, and work safety steps. The diagram helps you position your tools without blocking the airflow.

Laminar Air Flow Principle

The principle of Laminar Air Flow is based on:

Air moves in a single direction at a uniform speed.

Air passes through a HEPA filter before entering the workspace.

Particle free air washes the surface and removes airborne dirt.

The system depends on uniform airflow. Turbulence introduces contamination risk. You get the best results when the airflow remains steady and unobstructed.

Working Principle of Laminar Air Flow System

The working principle involves a sequence of controlled steps.

Ambient air enters the intake.

The pre filter traps large particles.

The blower pulls air toward the HEPA filter.

The HEPA filter removes particles up to 0.3 microns with high efficiency.

Filtered air enters the work zone in a single direction.

The airflow pushes old air out of the work zone.

The system depends on clean, filtered air. Your workspace stays protected because the airflow pushes away unwanted particles. The volume of airflow stays constant. This gives you a stable environment for sensitive tasks.

Components of Laminar Air Flow

HEPA Filter

The HEPA filter traps particles. It has a fiberglass mat designed to remove tiny particles. This filter is the central component that defines cleanliness level.

Pre Filter

The pre filter traps large particles like dust. It supports the HEPA filter and extends its working life.

Blower Unit

The blower pushes air through the filters. A stable blower unit helps maintain uniform airflow.

Work Chamber

The chamber holds your samples, tools, and media. The chamber walls protect airflow direction.

UV Light

Some units include UV light for surface sanitation before you begin work. You turn it off before handling samples.

Fluorescent Light

This gives you a bright and clear workspace without affecting airflow.

How Laminar Air Flow Works in Your Daily Tasks

When you start the system, the blower runs for a few minutes before you begin work. This helps the system reach stable airflow.

You clean the work surface with alcohol before placing samples. You keep your tools arranged along the airflow direction. You avoid blocking the airflow with your hands. You move your hands slowly to reduce turbulence.

When you place plates or flasks inside the chamber, the filtered air protects the media. The airflow pushes airborne dirt away from the opening of your containers.

You complete your tasks with minimal turbulence. You remove your samples once the lids are secure. You clean the chamber again after finishing.

Laminar Air Flow Uses

You use Laminar Air Flow systems across several technical fields.

Microbiology

You handle bacterial cultures, fungi, and sterile media. The system protects your plates, broths, and reagents from airborne particles. You pour plates, inoculate culture tubes, and transfer colonies in a cleaner space.

Tissue Culture Work

Plant and animal cell cultures need a controlled surface. Laminar Air Flow systems protect culture vessels from contamination. You prepare media, transfer tissues, and maintain culture flasks inside the airflow.

Pharmaceutical Filling

Powder filling, capsule handling, and vial preparation demand clean airflow. Laminar systems provide a particle controlled zone.

Electronics Assembly

Sensitive electronic chips, circuits, and wafer components require particle free handling. You use Laminar Air Flow systems to prevent particle deposition.

Chemistry Labs

Sample preparation for analytical instruments often requires a clean surface. You weigh chemicals, prepare standards, and handle glassware inside the chamber.

Quality Control Labs

QC labs in food, pharma, and chemical units use Laminar Air Flow systems for sterile sample handling. This gives consistent outcomes during testing.

College Labs

Training labs use Laminar systems to teach students sterile techniques. The airflow gives a controlled zone for basic handling tasks.

Best Practices for Laminar Air Flow Use

Before Starting Your Work

• Run the blower for a few minutes

• Turn on fluorescent light

• Turn off UV light

• Clean the surface with alcohol

• Keep tools ready before starting

• Tie hair and secure loose clothing

During Work

• Keep your movement slow

• Avoid placing your hands above open samples

• Keep your materials arranged

After Work

• Remove waste

• Clean the surface with alcohol

• Close the sash if available

• Run the blower for a short time

• Turn off the system

Common Mistakes to Avoid

• Working before airflow stabilizes

• Blocking airflow with large objects

• Rushing movements

• Touching the filter surface

• Leaving containers open for long

• Allowing clutter inside the chamber

Performance Checks

You check the airflow speed with an anemometer. You check the filter condition by pressure drop readings. You check cleanliness levels with settle plates.

Regular checks help maintain performance for sample preparation, sterile transfers, and QC tasks.

Why Laminar Air Flow Matters

Laminar Air Flow systems reduce contamination risk. You get a controlled surface for sensitive work. Your results stay consistent. Airborne dirt stays away from your open plates, flasks, and instruments.

A controlled system improves your sample quality in microbiology, tissue culture, electronics, and chemical labs.

Wrapping Notes

Laminar Air Flow systems provide a particle controlled zone with uniform airflow. You use these systems to protect sensitive samples. The airflow principle depends on HEPA filtration and unidirectional movement. You pick a model based on your lab, your tasks, and your space. You get better results when you follow proper technique, maintain the filters, and arrange your tools without blocking airflow.