A screw gauge, or a micrometer screw gauge, is a highly accurate precision instrument capable of measuring very small dimensions. It is widely used in laboratories, workshops, mechanical engineering, metal industries, and educational institutes. The screw gauge can measure the thickness, diameter, or length of small objects that cannot be accurately measured using a ruler or vernier caliper.

The principle of measurement in a screw gauge is that of the screw principle, where the rotational motion of the screw is converted to linear motion. When the thimble gets rotated, the spindle gets pushed or pulled through a very finely cut screw. This linear motion is then used to measure very small distances, often even as small as 0.01 mm or sometimes 0.001 mm (depending on the type of screw gauge).

Due to its high accuracy, a screw gauge is used to measure objects that are difficult to measure, such as thin wires, small rods, sheets, and parts of metallic objects, as well as in some laboratory experiments. This tool is certainly among the very reliable ones when precision is a must.

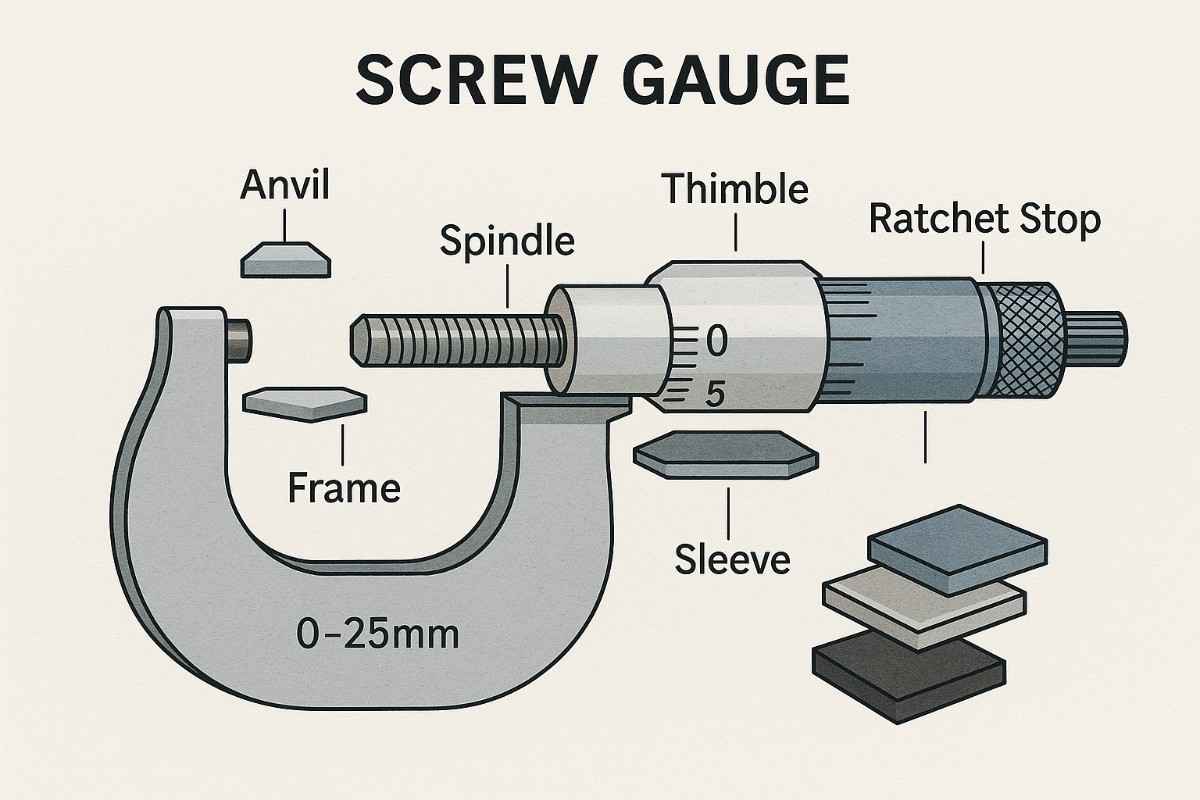

Screw Gauge Diagram and Components

A typical screw gauge consists of several components arranged systematically to ensure accurate measurement. A labeled diagram would usually show:

1. Frame (U-Frame)

The frame is the rigid, U-shaped structure that holds all other parts together. It provides stability while taking measurements.

2. Anvil

The a nvil is a fixed, flat-surfaced stud located on one side of the frame. When an object is placed between the spindle and the anvil, measurement takes place.

3. Spindle

The spindle is a movable screw that moves toward or away from the anvil as the thimble is rotated. It is responsible for actually contacting the object being measured.

4. Sleeve (Barrel)

The sleeve is the stationary cylindrical part on which the main scale is engraved. The main scale is usually marked in millim

5. Thimble

The thimble is a rotating cylindrical component attached to the spindle. It carries the circular scale, which works together with the main scale to give accurate readings.

6. Circular Scale (Thimble Scale)

Engraved on the thimble, the circular scale typically has 50 or 100 divisions. This scale indicates fractional millimeter readings.

7. Ratchet

The ratchet ensures uniform pressure while measuring. It prevents the user from applying excessive force, which could damage the instrument or distort the reading.

8. Locking Screw / Lock Nut

This is used to fix the spindle in position after the object is placed between the anvil and spindle. It ensures stable and accurate reading.

This diagram helps students understand how the instrument works and which parts are involved during measurement.

Least Count of Screw Gauge (Beginner-Friendly Explanation)

The main scale of a screw gauge usually has 10 divisions for 1 centimeter.

This means the smallest division on the main scale is 1 mm, and that value is called the pitch (p) of the screw gauge. Pitch simply means how much the spindle moves forward when it makes one full rotation.

The circular scale of the screw gauge has 100 divisions, written as n = 100.

Least Count Formula

Least Count = Pitch / Number of circular divisions

Putting the values:

Least Count = 1 mm / 100

= 0.01 mm

= 0.001 cm

So, the least count of a screw gauge is 0.01 mm, which means this is the smallest measurement it can read accurately.

Characteristics of Screw Gauge

A screw gauge is a precise measuring tool used to measure very small lengths like the thickness of wires or the diameter of tiny objects. It is known for its high accuracy, smooth working, and ability to measure minute differences. Below is a simple table explaining its main characteristics:

| Characteristic | Explanation (Easy Words) |

| Pitch | The distance the spindle moves forward in one full rotation. Usually 1 mm. |

| Least Count | The smallest value it can measure. For most screw gauges, it is 0.01 mm. |

| Main Scale | A linear scale on the sleeve that shows measurements in millimeters. |

| Circular Scale | A rotating scale with 100 divisions, used to get very small readings. |

| Accuracy | It gives very precise measurements, more accurate than a vernier caliper. |

| Zero Error | When the scale does not start at zero. It must be corrected before reading. |

| Measuring Range | It can measure very small dimensions like wire thickness or small diameters. |

| Spindle & Anvil | These two parts hold the object tightly for accurate measurement. |

| Ratchet Knob | Ensures the spindle applies equal pressure so the reading is correct. |

| Durability | Made of strong metal, so it lasts long and stays accurate. |

Important Terms Used in a Screw Gauge

A screw gauge is based on some essential terms without which it would be impossible to unearth the distances moved by the screw and the accuracy of the small objects that are measured. Pitch, main scale, circular scale, and least count are the terms that guide the working of the screw gauge as well as the fineness of the measurements. Below is a straightforward table summarizing the meanings of the terms:

| Term | Simple Meaning | Typical Value |

| Pitch | Distance moved by the spindle in one full rotation. | 1 mm |

| Least Count | Smallest measurement the screw gauge can read. | 0.01 mm |

| Main Scale | Fixed scale on the sleeve used to read whole millimeters. | Divisions in mm |

| Circular Scale | Rotating scale used to read small fractions of a millimeter. | 100 divisions |

Uses of Screw Gauge

A screw gauge has high accuracy and is used for measuring very small lengths. It becomes more useful for measuring thin objects where very precise measurements are required. Its main applications are simply described below:

- To measure the diameter of thin wires (like copper wire or fuse wire).

- To measure the thickness of small metal sheets which are too thin for a vernier caliper.

- To measure the diameter of small cylinders, such as rods, pins, or small bolts.

- To check the thickness of paper or plastic films used in laboratories and industries.

- To measure the diameter of small spherical objects like tiny balls or beads.

- In physics laboratories for experiments involving thickness, diameter, and volume calculations.

- In mechanical and engineering works where very precise measurements are required.

Solved Examples of Screw Gauge

Example 1—Measure diameter of a thin wire

Given:

- Main scale reading = 3.00 mm (i.e., 3 divisions on main scale)

- Circular scale reading = 28 divisions

Steps:

- LC = 0.01 mm.

- Circular contribution = circular reading × LC = 28 × 0.01 mm = 0.28 mm.

- Final reading = Main scale + Circular contribution = 3.00 mm + 0.28 mm = 3.28 mm.

Answer: Diameter = 3.28 mm.

Example 2—Measure thickness with zero error (positive zero error)

Given:

- Main scale reading = 2.40 mm

- Circular scale reading = 12 divisions

- Zero error = +0.02 mm (positive means when closed the reading shows +0.02 mm extra)

Steps:

- LC = 0.01 mm.

- Circular contribution = 12 × 0.01 = 0.12 mm.

- Raw final reading = 2.40 + 0.12 = 2.52 mm.

- Corrected reading = Raw final reading − Zero error = 2.52 − 0.02 = 2.50 mm.

Answer: Thickness = 2.50 mm.

Example 3—Measure diameter with negative zero error

Given:

- Main scale reading = 1.80 mm

- Circular scale reading = 5 divisions

- Zero error = −0.01 mm (negative means when closed the instrument shows −0.01 mm i.e. it reads less)

Steps:

- LC = 0.01 mm.

- Circular contribution = 5 × 0.01 = 0.05 mm.

- Raw final reading = 1.80 + 0.05 = 1.85 mm.

- Corrected reading = Raw final reading − (Zero error).

- Since zero error is negative (−0.01), subtracting negative becomes addition:

- Corrected = 1.85 − (−0.01) = 1.85 + 0.01 = 1.86 mm.

Answer: Diameter = 1.86 mm.

Example 4—Small object where main scale reads zero

Given:

- Main scale reading = 0.00 mm (object less than 1 mm so main scale reads zero)

- Circular scale reading = 63 divisions

- Zero error = 0

Steps:

- LC = 0.01 mm.

- Circular contribution = 63 × 0.01 = 0.63 mm.

- Final reading = 0.00 + 0.63 = 0.63 mm.

Answer: Size = 0.63 mm.

Quick checklist for taking correct readings

- Note the least count (usually 0.01 mm).

- Read the main scale (millimeters)—write it down with two decimal places if needed (e.g., 2.40 mm).

- Read the circular scale (number of divisions aligned). Multiply by LC.

- Add main and circular to get raw reading.

- Check for zero error and correct:

- If zero error is +ve, subtract it.

- If zero error is −ve, subtracting negative adds it.

- Write the final answer with the correct units (mm).