Description

Software designed for industrial materials, Scientists, Metallurgists, Laboratory technicians, and R & D engineers who need improved solutions for quality control and product development.

Material Plus is computer-aided quantitative analysis results follows strictly ISO & ASTM technical standards.

The software is powerful to handle different image format BMP, TIFF, GIF, JPEG etc. It support many cameras,

USB 2.0 & USB 3.0, devices, TWAIN input devices.

This exceptional software produces as much as 80% more picture points in image window than competitive softwares.

The image processing technique will streamline image capture, measurement and enhancement, while improving

the accuracy of your results. Live measurement saves lot of your time.

Modules of Material Plus

Some of the major modules in Material Plus are as follows:

CAMERA

One can select different display/capture sizes along with other setting like white balance, brightness,

contrast, Hue, Saturation can be changed on live displayed image. Once all setting are done, image can be

captured in appropriate folder for appropriate analysis.

CALIBRATION

Calibration should be performed on all the objectives of the microscope, where Digital Camera is installed.

Calibration should be performed only when all hardwares are finally fixed. In case of readjustments or

replacement of any part, calibration should be done again.

MEASUREMENT

With the Measurement module one can obtain measurement on manually drawn lines on traces, shapes or

by outlining an object Which can be accumulated and logged on to the results worksheet from where they

can be stored to a file, printed or transferred to spread sheet for further analysis or statistics.

GRAIN SIZE

This module can quickly perform automatic, objective and repeatable grain size analysis to industrial

standards to determine ferritic & austenitic grain size in steed, international method ASTM E-112, E-93,

E1181 are used.

POROSITY

Pores, due to their contrast with the rest of the image, are relatively easy to detect automatically the module

allows a user to recognize and measure the porosity in the material according to ASTM B276 Standard

Thresholding readily accomplished using gray scale techniques. The dark phase of porosity is detected in

red bitplanes.

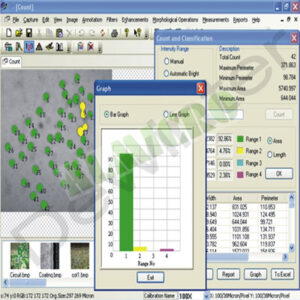

SEGMENTATION

Segmentation is a method of image partitioning on the intensity / grayscale range of its parts. Since a

phase is detected and its area is estimated on the basis of its intensity / grayscale, an option for delineating

phases from the histogram is also provided. Multiple phases are identify by colored overlays and can be

simultaneously displayed in the same field of view.

DECARBURIZATION

The module is used to determine the depth of Decarburisation form the changes in structural quality In

partial decarburisation is where the carbon content is reduced but there is on total Decarburisation is

measured in work piece to the limit of the limit of the ferritin layer with almost total carbon removal if

compliance ASTM E-1077-91 Standard

CAMERA

GRAIN SIZE

CALIBRATION

POROSITY

MEASUREMENT

SEGMENTATION

DECARBURIZATION

SG IRON

SG Cast Iron or Nodules are also called DUCTILE IRON or SPHEROIDAL GRAPHITE IRON. Nodules Cast

Iron are produce from graphite during Solidification. Ductile Iron Analysis module provides a chance to

analyze an image on the basis of ASTM A-247-67, ISO-945-1.

GRAY IRON

Grey Iron or grey Cast Iron is a type of Cast iron that has a graphitic micro structure. Grey iron analysis

module provides a chance to analyze an image on the basis of ASTM A-247-67, ISO 945-1.

SG IRON

GREY IRON

4

Modules of Material Plus

COATING THICKNESS

Plating or coating thickness is determined by cross-sectional microscopy method. The specimen is cross-

sectioned, mounted, polished and microscopically evaluated for measuring the plating or coating thickness,

sometimes, etching of the core base metal may be necessary to accurately measure the coating or plating

thickness. The test method covers measurements of the local thickness of mental and oxide coatings by the

microscopical examination of cross sections using an optical microscope.

SPHERODIZATION

This module is designed to analyze spheroidal graphite (nodules). The nodules are separated from non-

nodules on predefined spheroidicity. Nodules acquire blue color and non-nodule get red color. Nodules

from (designated by Roman numbers from I to VI) and size (designated by Arabic numbers 1 to 8) are

reported along with the calculated nodules/sq mm.

INCLUSION

Using Material Plus software a user can identify four types of inclusion.

SULFIDE TYPE (A TYPE), ALUMINA TYPE (B TYPE)

SILICATE TYPE (C TYPE), GLOBULAR TYPE (D TYPE)

Each type is further divided into Thin and Heavy, based on the width parameters.

CARBIDE

Iron carbide or Cementite is an intermetallic component of iron and Carbon. While iron Carbide as present

in most steels and Cast Iron, it is produced as raw material in the iron carbide process, which belongs to the

family of alternative iron making technology. CARBIDE

COATING THICKNESS

SPHERODIZATION

INCLUSION

GRAIN SIZE

SETTINGS

The Module SETTING is designed to set various parameters for first time when software is installed. The

setting options are available to choose ISO/ASTM standard calibration, setting in report format, setting of

various parameter on printed image in report. Once all settings are done, you need one button click for

all Analysis. All settings are stored till you change them in future. Do not change them in routine, it is not

necessary.

REPORTS

All reports are saved in the folder and can be retrieve anytime in future.

1. Measurement | 2. Grain Size | 3. Porosity | 4. Decarburization | 5. Segmentation | 6. SG Iron |

7. Gray Iron

GALLERY

Four Folders are available to view any Captured images. The folders are:

1. Nodularity | 2. Flake | 3. Carbide | 4. Line Measurement | 5. Grain Size | 6. Porosity | 7. Decarburization |

8. Segmentation | 9. SG Iron | 10. Coating Thickness

Reviews

There are no reviews yet.