Description

Technical Specification Table

| Specification | Details |

|---|---|

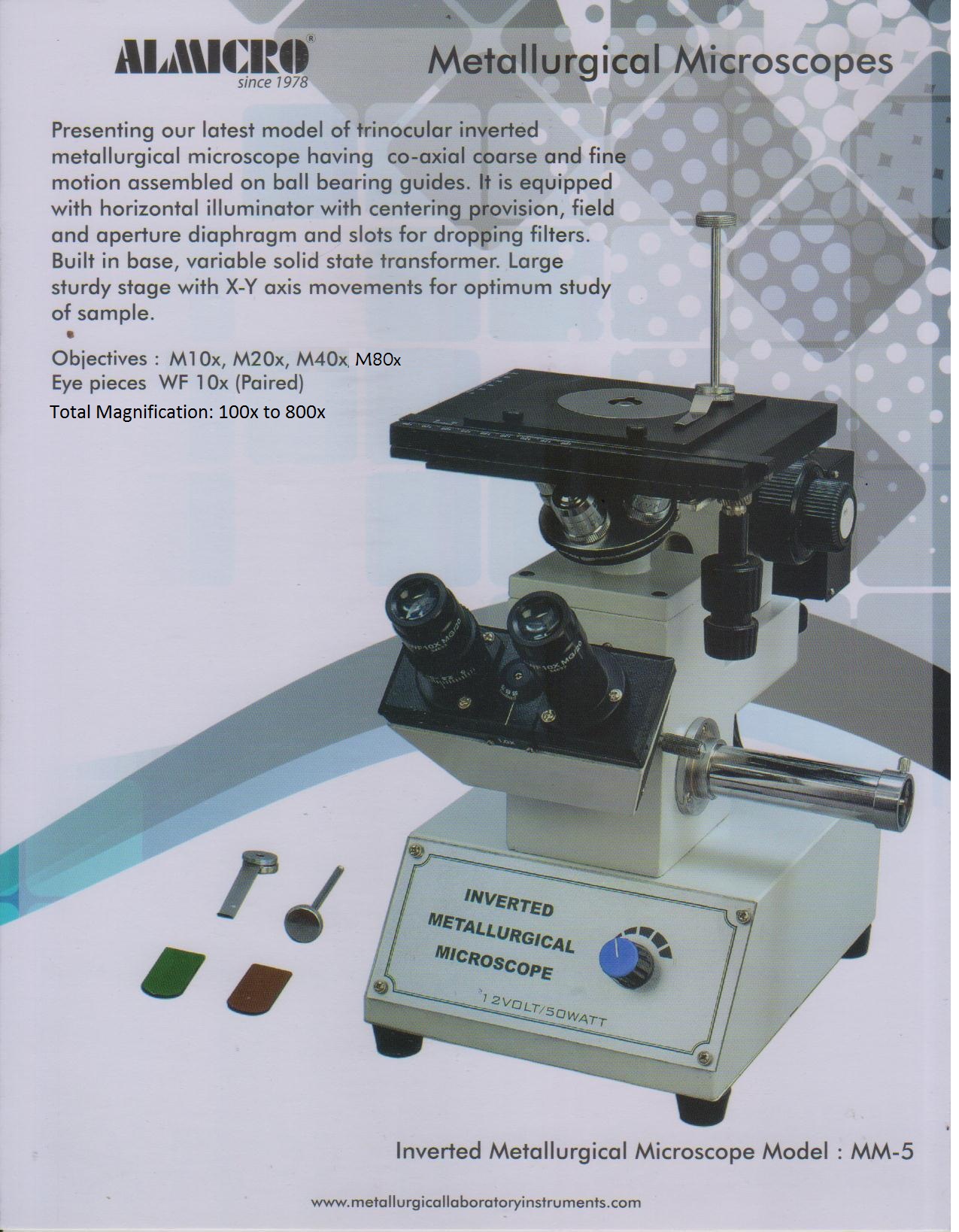

| Model | Inverted Metallurgical Microscope MM-5 |

| Head Type | Compensation-free trinocular head, 45 degree inclined |

| Stage | Double layer 172 mm x 142 mm |

| Stage Movement | 30 mm x 30 mm |

| Focusing | Coaxial coarse and fine focusing, rack & pinion |

| Fine Focus Value | 0.002 mm |

| Illumination | 12V / 20W halogen lamp with aperture and field diaphragm |

| Polarizing Device | 360 degree analyzer and removable polarizer |

| Design | Inverted metallurgical configuration |

Key Features

• Trinocular head with compensation free optics for clear and stable imaging

• 45 degree inclined viewing for comfortable long-term use

• Double-layer mechanical stage 172 x 142 mm for smooth sample movement

• Stage movement range of 30 x 30 mm for precise positioning

• Coaxial coarse and fine focusing with rack and pinion system

• Fine focus scale value of 0.002 mm for accurate depth control

• 12V 20W halogen illumination with aperture and field diaphragms

• Inverted design suited for metallurgical samples and polished surfaces

• Polarizing device with 360 degree rotating analyzer

• Removable polarizer for flexible observation methods

• Stable build for industrial and research environments

Working Principle

The microscope illuminates the sample from above using the halogen lamp. Light reflects off the polished metal surface and enters the objective. The inverted optical design allows users to place larger and heavier samples on the stage without cutting or thinning. The objectives magnify the sample, and the trinocular head presents the image clearly. The fine focus system adjusts the height in small steps to achieve sharp clarity. The polarizing attachment improves contrast and helps analyze grain structures and material defects.

Use Cases

• Metallurgical labs studying grain structure and surface defects

• Industrial quality control departments inspecting metal components

• Research centers working on alloys, coatings, and material development

• Failure analysis labs examining fractures and machining marks

• Educational institutions teaching metallography and material science

• Production units monitoring heat treatment and metal finishing processes

Reviews

There are no reviews yet.