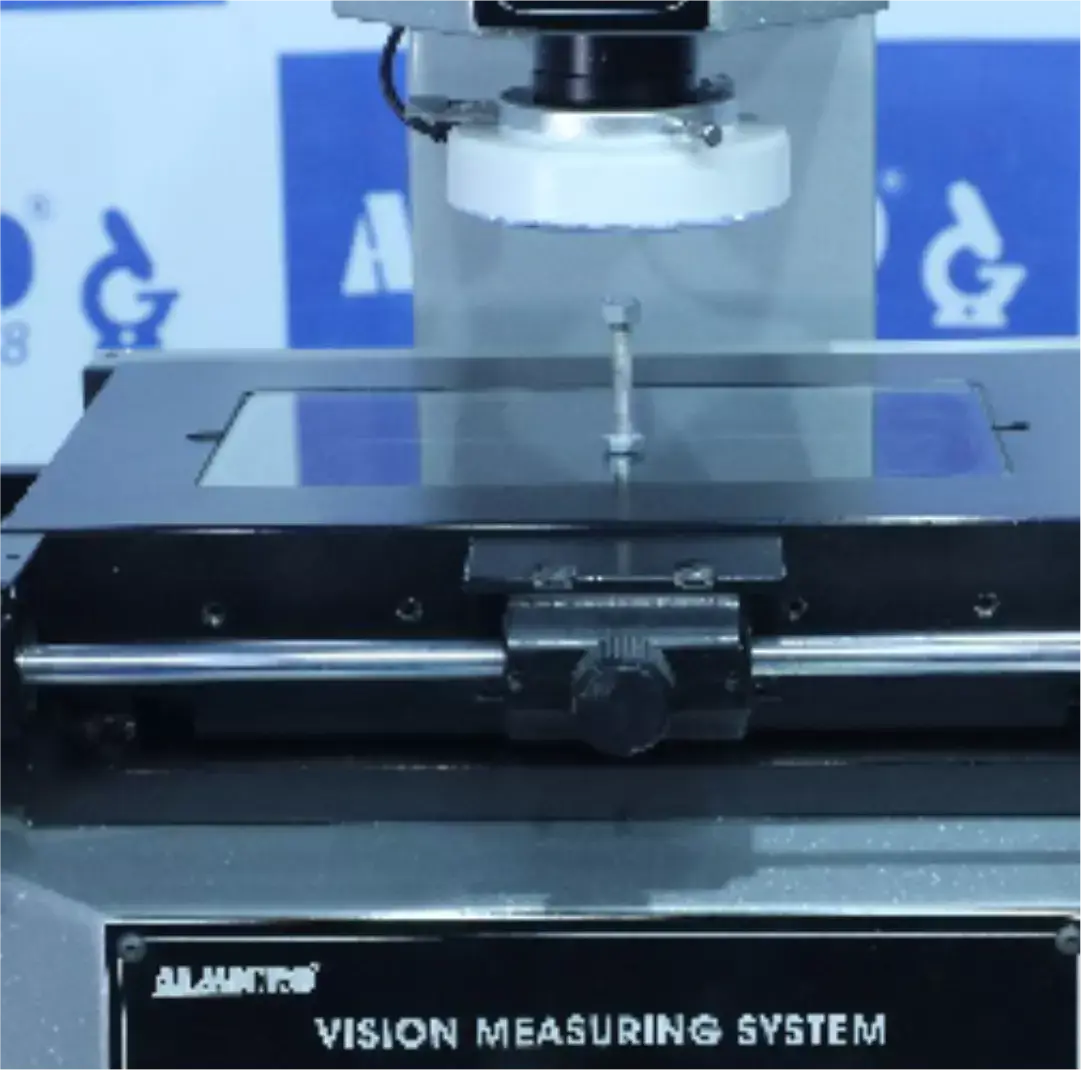

Description

Used in 3 axis measurement as well as 3D measurement, this instrument is a high precision and high efficiency measuring machine that integrates optics, machinery and electronics. It is mainly used in the field of machinery, electronics, instrument, meter, watch, light industry, plastics as well as measuring chambers, laboratories of institutes and universities, research institutes, metrological verification departments and workshops, etc.

Features꞉

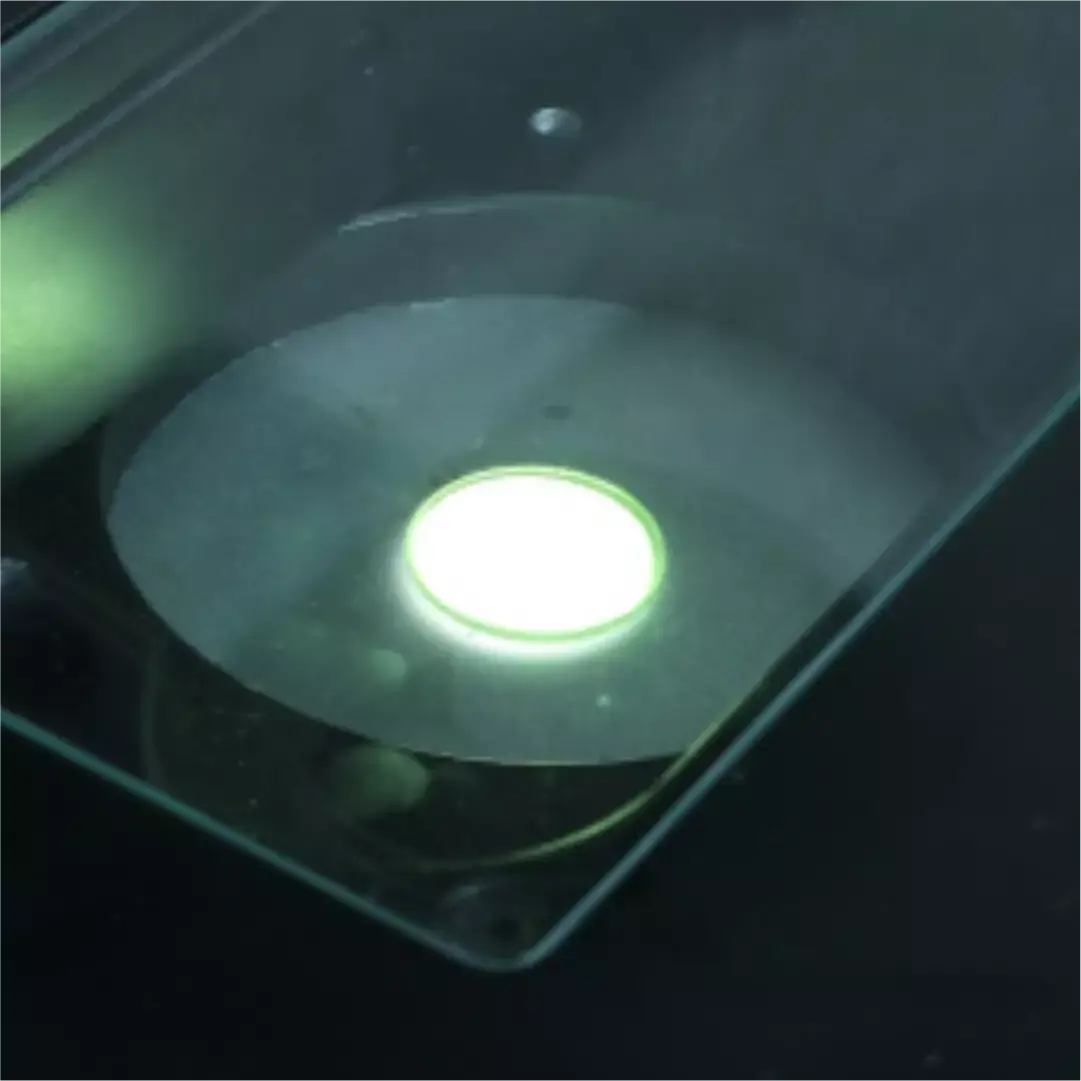

- Various kinds of lighting Meets various requirements for customers.

- Data processing, data display, data input, and data output.

- Pragmatic workpiece straightening feature.

- Optional Foot‑switch is matched with measuring software, which makes operation easier.

SOFTWARE FEATURES

QMS3D-M measuring software, a manual measuring machine software and probe measuring application software as well not only be used to analyze, process and measure the workpiece in the two- coordinate visually but also be used in three-coordinate measuring when a probe is equipped. This software is widely used in various precision manufacturing industries such as handset components, mold, tooling, electronics, telecommunication, machinery, hardware, plastic, instrument, meter, PCB, LCD, etc. Materials can be measured involve in metal, plastic, rubber, glass, PCB, ceramic, etc.

- Various kinds of report formats

- Rig measurement, scanning, image navigation, multiple measuring methods and multiple construction methods.

- Tolerance features upper-lower control limit pass/fail feature

- Feature of calibrating pixel.

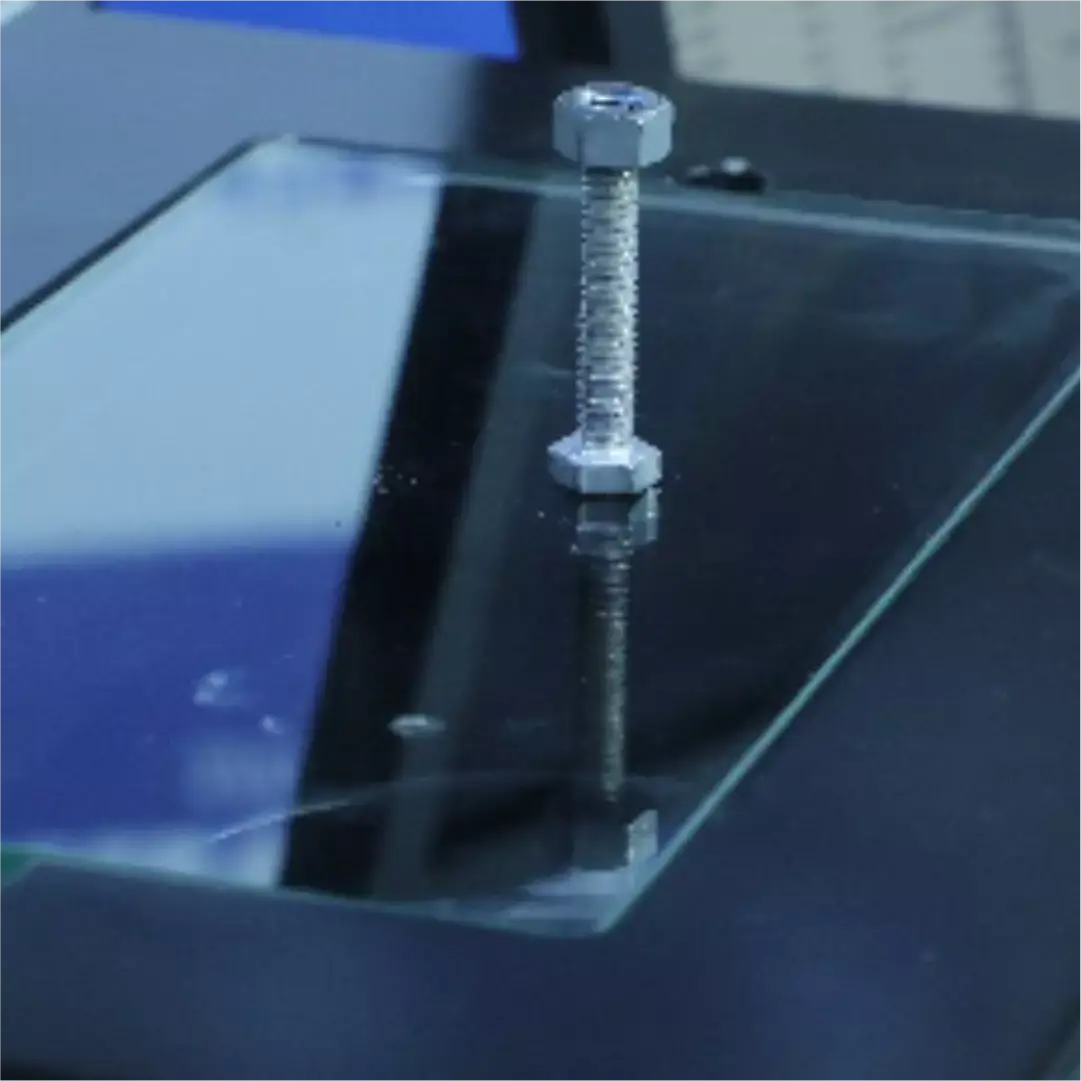

- Image and probe measurement (for third dimension optional)

- Focus assist, multiple measuring methods, and multiple construction methods.

- Scanning system.

- Program Running feature

Key features:

- Various kinds of basic geometrical elements measured by image and probe, such as point, line, circle, arc, ellipse, rectangle, key slot, plane, skewness, flatness, perpendicularity, parallelism etc.

- Can be output into Word, Excel and AutoCAD.

- Professional SPC (Statistical Process Control) tool – Production process can be effectively controlled and quality of the product can be continuously improved.

- User-friendly human-computer interface.

- Multi-functional and user-friendly measuring procedure.

- Fully compatible with WIN7 OS and 17 inches display.

- Result window with multi kind features like inclined line, tetrahedron line, irregular curve features.

- Crossline selection as per convenient, screen calibration including profile projector features with crosshair line measurement.

- DXF,CAD transfer facility with Realtime graphical representation along with related measured features etc.

OPTIONAL:

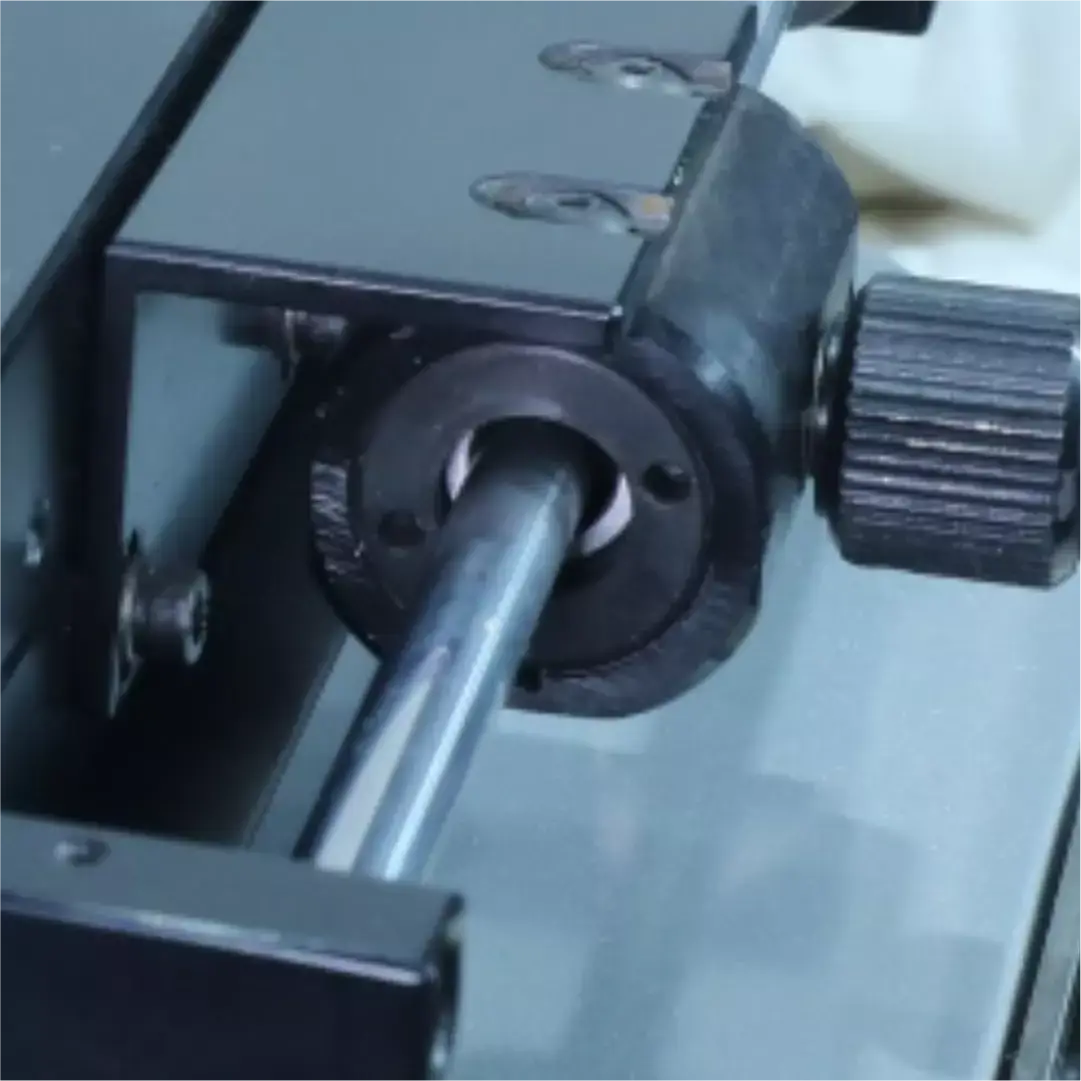

- Sensor synchronization includes synchronization of probe image and, synchronization of shifter and image.

- Touch Probe Optional.

| Working | Model | ALM VMS- 2.5D in mm | ALM VMS- 3D in mm (3 Axis) |

| Metal Table size | 300x300x150 | 300x300x150 | |

| Travel | 200x200x150 | 200x200x150 | |

| Z-Axis (mm) | 150 (can be customized to 400) | ||

| Consistency error of origin in different sections | G series E₀ ≤30 (every 100mm displacement in Z Axis | ||

| Linear scale resolution: 0.0005mm. X, Y indication error: (2.5+L/100) µm (L is the length of the measured object. Unit: mm) | |||

| Working | Almicro VMS-M | ||

| 1/3″ color CCD camera | |||

| Zoom lens magnification: 0.7X~4.5X | |||

| Magnification: 2.6.6~171X (19.5″ monitor) | |||

| Object view: 8.1mm~1.3mm | |||

| Surface lighting and transmission lighting both adopt adjustable | |||

Reviews

There are no reviews yet.